Simulation and Modeling of Lignocellulosic Biomass Conversion Using the BIOFEED Databank in Aspen Plus

Background

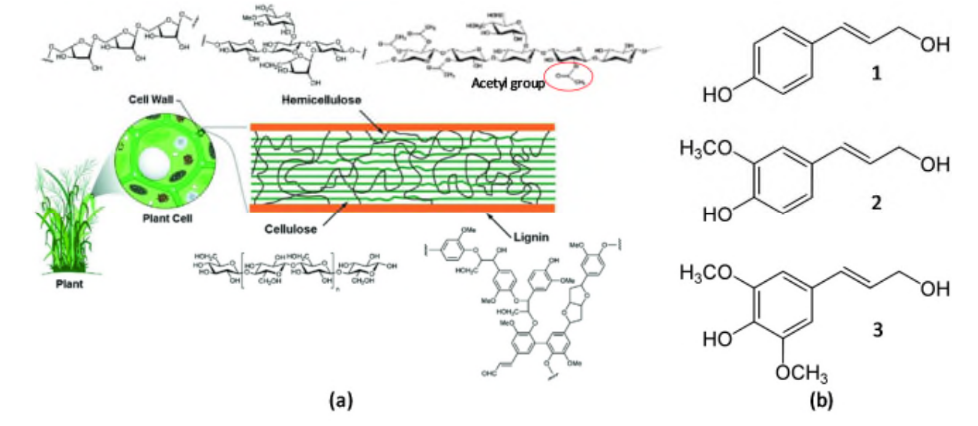

Lignocellulosic biomass—composed of cellulose, hemicellulose, and lignin—is a key renewable resource for sustainable biofuel production. Cellulose and hemicellulose are carbohydrate polymers made up of C6 and C5 sugars, while lignin is a complex aromatic polymer built from lignol monomers. These structural components form the rigid framework of plant cell walls (Figure a), with lignin derived from key monomers such as paracoumaryl, coniferyl, and sinapyl alcohols (Figure b).

Variations in biomass composition across different species and plant parts influence their thermal behavior during processes like pyrolysis and gasification. To simulate these reactions accurately in Aspen Plus, biomass must be defined using conventional components with known thermodynamic properties. The BIOFEED databank supports this by providing detailed, pre-defined compositions for over 500 lignocellulosic feedstocks, enabling more realistic process modeling and optimization.

Project Description

In response to the growing need for sustainable energy alternatives, this simulation project focuses on the conversion of lignocellulosic biomass into renewable fuels using Aspen Plus. By incorporating the BIOFEED databank, the model captures the complex composition and thermal decomposition behavior of biomass constituents such as cellulose, hemicellulose, and lignin. Utilizing RYIELD and RGIBBS reactor models, the simulation accurately represents non-conventional feed breakdown and predicts the distribution of key products including syngas, bio-oil, and char.

The process flowsheet was structured to replicate industrial biomass conversion systems, with emphasis on pyrolysis and gasification pathways. Sensitivity analyses were conducted across a range of operating parameters—such as temperature, pressure, and feed composition—to evaluate their impact on conversion efficiency and product yields. This project highlights advanced competency in process simulation, thermodynamic modeling, and renewable energy system design, providing valuable insights for the development of efficient and environmentally responsible bioenergy technologies.

Project Objectives

This project aims to simulate and optimize the conversion of lignocellulosic biomass into renewable fuels using Aspen Plus, with a focus on accurate modeling and sustainable process design.

Model thermal conversion of lignocellulosic biomass using Aspen Plus.

Integrate the BIOFEED databank for realistic feedstock characterization.

Simulate non-conventional biomass breakdown via RYIELD and RGIBBS reactors.

Analyze product distribution (syngas, bio-oil, and char) under varying conditions.

Evaluate process efficiency and identify optimal operating parameters.

Contribute to the development of clean and sustainable bioenergy technologies.

Feedstock Conversion Using RYIELD

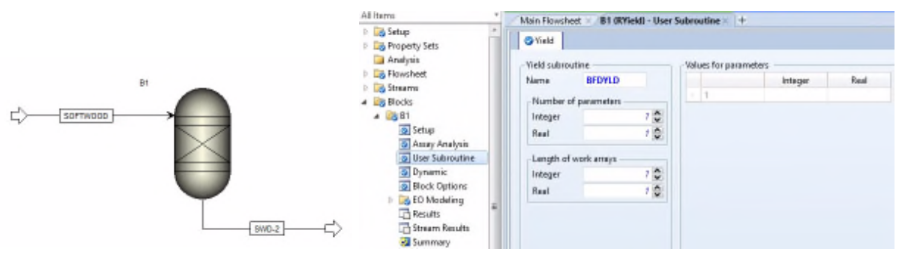

In Aspen Plus, converting BIOFEED components into conventional base components requires a Fortran subroutine (BFDYLD.F) implemented in the RYIELD reactor. This subroutine uses the BIOPOS property to map biomass components to their base forms without relying on component names. As illustrated in Figure 3, the RYIELD block is configured to apply this subroutine, allowing accurate decomposition of feedstock into elemental or simplified species for downstream processing.

Project Insights

Advanced Biomass Characterization

Developed a flowsheet with reactors, separators, and heat exchangers.

Tracked mass and energy balances to ensure process consistency.

Sustainable Bioenergy Optimization

Applied RYIELD reactor with user-defined Fortran subroutine.

Enabled decomposition of biomass into base chemical components.

Process Flow Simulation and Analysis

Developed a flowsheet with reactors, separators, and heat exchangers.

Tracked mass and energy balances to ensure process consistency.

Sustainable Bioenergy Optimization

Evaluated product yields for syngas, bio-oil, and solid char.

Identified optimal operating conditions for efficiency and output.

Conclusion

The simulation of lignocellulosic biomass conversion using the BIOFEED databank and Aspen Plus demonstrated the feasibility of modeling complex bio-based feedstocks with precision. By integrating a custom Fortran-based RYIELD subroutine, the process enabled accurate decomposition of biomass into its base components, facilitating downstream analysis and optimization. This approach not only advances the understanding of biomass conversion pathways but also supports the development of efficient, sustainable biorefinery processes for renewable energy and chemical production.