Vessel Depressurization Modeling in Aspen Plus Dynamics

Project Description

Depressurization is a vital safety and operational procedure in process systems, particularly during shutdowns or emergency scenarios. In this simulation, Aspen Plus Dynamics is used to model the controlled depressurization of a vessel initially pressurized at approximately 49 psi. The model simulates the time-dependent pressure decay after isolating the feed and venting to atmospheric conditions. A dedicated task is configured to close the feed valve and define the boundary pressure, while all controllers are set to manual to observe natural system behavior. This case study offers valuable insight into pressure relief dynamics and system response during depressurization events.

Project Objectives

This project aims to simulate and analyze the depressurization behavior of a pressurized vessel using Aspen Plus Dynamics. The focus is on safety evaluation and system response under controlled release scenarios. Objectives are listed below:

To simulate time-dependent pressure decay during vessel depressurization under atmospheric venting.

To configure manual control settings and tasks that replicate emergency shutdown behavior.

To evaluate system response and pressure relief effectiveness in dynamic conditions.

To provide a foundation for safety assessment and design validation of pressure relief systems.

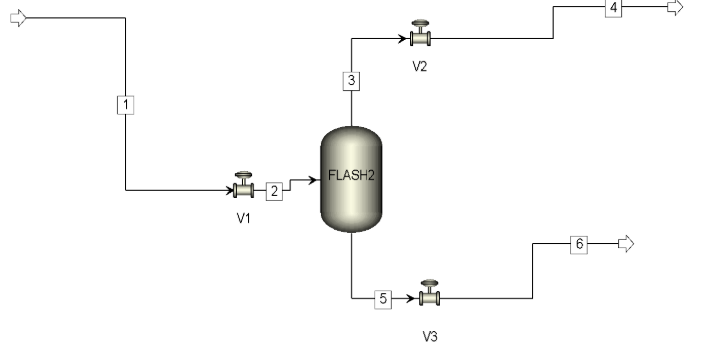

Process Flow Diagram

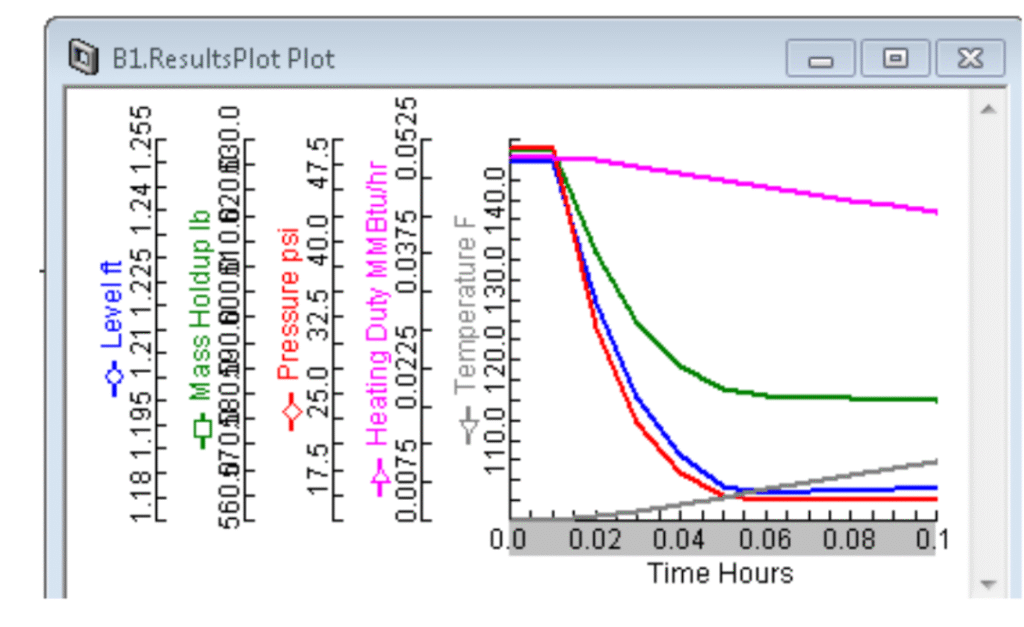

Dynamic Simulation of Process Disturbance Response

This project simulates the unsteady-state behavior of a process unit in Aspen Plus Dynamics following a sudden disturbance. Key parameters such as temperature, pressure, liquid level, heat duty, and mass holdup are tracked over time. The model demonstrates how the system responds and eventually stabilizes, offering insight into transient dynamics and control behavior.

Project Insights

Depressurization

• Models pressure drop from 49 psi to atmospheric levels.

• Simulates emergency shutdown or venting scenarios.

Task Implementation

• Feed valve is closed using a task event.

• Boundary condition shifts to ambient pressure.

Controller Setup

• All controllers are set to manual mode.

• Enables observation of natural system decay.

Engineering Relevance

• Useful for safety and relief system analysis.

• Estimates time required for full depressurization

Conclusion

This simulation effectively demonstrates the depressurization behavior of a pressurized vessel using Aspen Plus Dynamics. By closing the feed valve and venting to atmospheric pressure, the model captures real-time pressure decay without active control intervention. The study provides valuable insights into emergency response dynamics and serves as a foundational tool for evaluating relief system performance during process shutdown scenarios.