Estimating Low Heating Value (LHV) of Biomass-Based Non-Conventional Components Using Aspen Plus

Project Description

Estimating the Low Heating Value (LHV) of biomass-based non-conventional components in Aspen Plus involves a strategic modeling approach that bridges the gap between complex solid fuels and process simulation capabilities. By integrating RYield and RStoic reactor blocks, the methodology simulates the breakdown of biomass into conventional components followed by complete combustion, enabling accurate energy release calculations.

The model utilizes ultimate, proximate, and sulfur analyses to define the composition of the non-conventional biomass, which is processed using an Excel-linked calculator block to dynamically compute both the High Heating Value (HHV) and LHV. The conversion from HHV (dry basis) to LHV (wet basis) incorporates corrections for moisture content and the latent heat of water vapor, making the results more applicable to real-world conditions.

By employing the HCOALGEN property method, the simulation ensures reliable estimation of enthalpy of combustion (HCOMB), supporting both empirical and user-defined values. This approach enables more realistic combustion modeling of biomass solids, facilitates energy balance analysis, and enhances process optimization. The framework is modular, reusable, and adaptable—making it ideal for evaluating various biomass feedstocks in bioenergy systems, addressing limitations in Aspen’s handling of non-conventional materials, and supporting scalable design decisions.

Project Objectives

This project aims to simulate the combustion behavior of biomass-based non-conventional components in Aspen Plus. By integrating experimental data and process simulation techniques, the model facilitates accurate estimation of the Low Heating Value (LHV). The approach ensures a realistic evaluation of biomass energy potential under wet conditions.

Simulate biomass decomposition and combustion using RYield and RStoic blocks.

Estimate LHV on a wet basis by correcting HHV with moisture and latent heat data.

Integrate ultimate, proximate, and sulfur analyses using Excel-based calculator blocks.

Apply HCOALGEN model to define or estimate the heat of combustion.

Develop a reusable simulation framework for evaluating various biomass feedstocks.

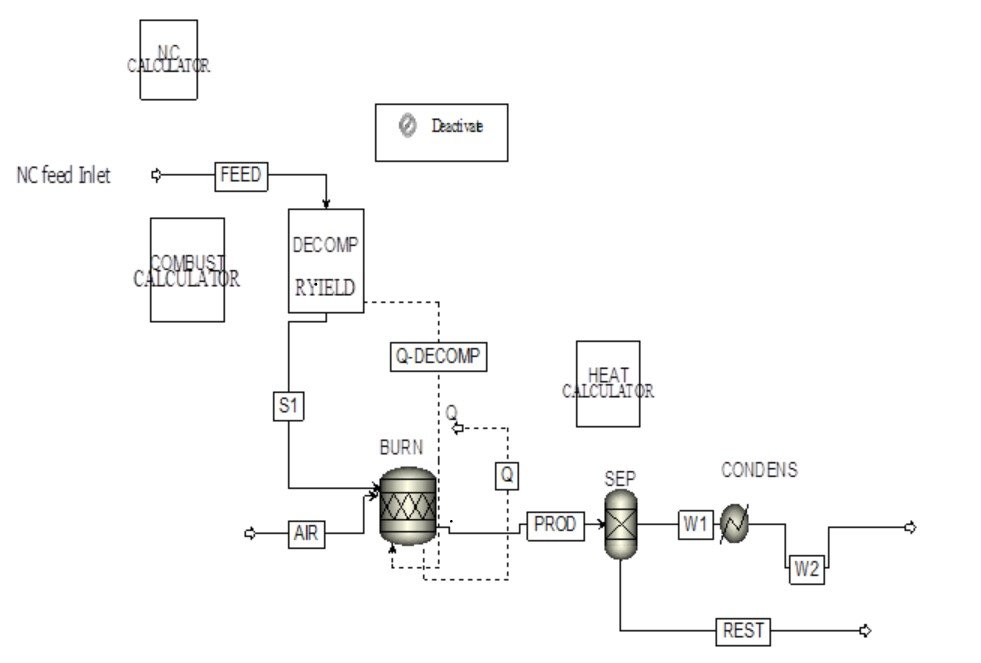

Process Flow Diagram

Project Insights

LHV Estimation Approach

- Converts NC biomass to conventional components using RYield and RStoic.

- Calculates LHV on wet basis by adjusting HHV for moisture content.

Data-Driven Modeling

- Integrates ultimate, proximate, and sulfur analyses via Excel calculators.

- Applies HCOALGEN model for user-defined or estimated combustion heat.

Structured Flowsheet Design

- Uses DECOMP for decomposition and BURN for combustion.

- Adaptable framework for evaluating biomass in energy systems.

Reliable Combustion Simulation

- Addresses databank mismatches in heat of formation.

- Supports realistic energy balance and performance analysis.

Conclusion

The simulation successfully demonstrates a reliable and systematic approach to estimate the Low Heating Value (LHV) of biomass-based non-conventional components using Aspen Plus. By integrating decomposition via RYield, complete combustion via RStoic, and Excel-based calculators for elemental analyses, the model provides accurate LHV predictions on a wet basis. The use of the HCOALGEN model ensures flexibility in handling user-defined or estimated combustion data. This framework not only supports realistic energy evaluations but also offers a scalable solution for assessing diverse biomass feedstocks in bioenergy applications.