Rigorous Aspen Plus Simulation and Economic Analysis of CO₂ and H₂S Removal from Natural Gas Using Potassium Carbonate Solvent

Description

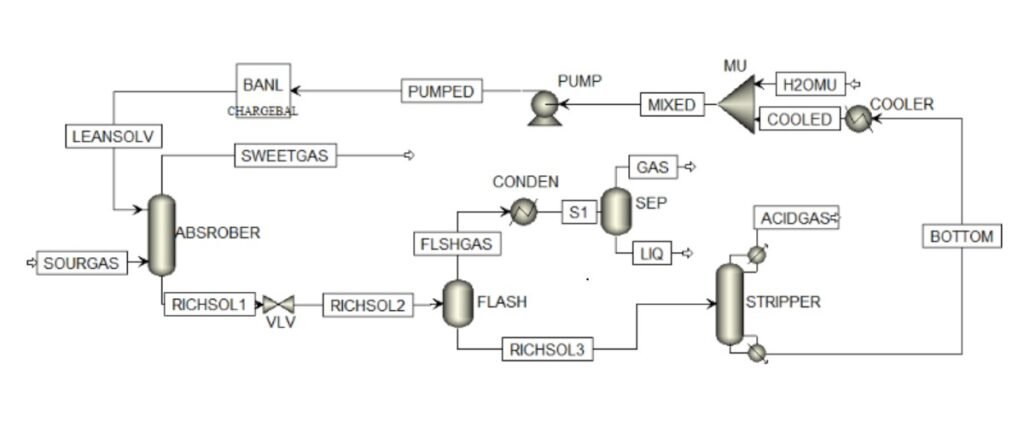

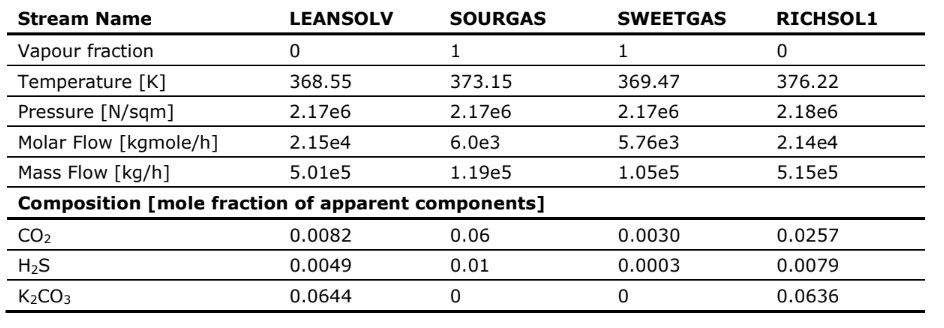

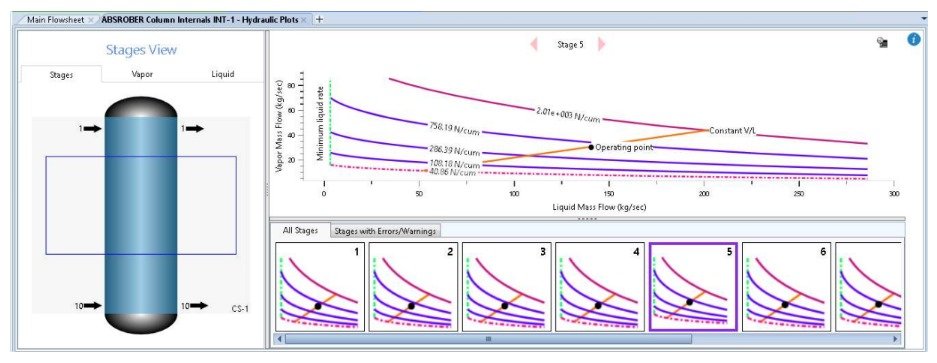

A rigorous Aspen Plus simulation was developed to model the removal of CO₂ and H₂S from natural gas using potassium carbonate (K₂CO₃) as the chemical solvent. The process treats 1 million metric tons of natural gas per year and is based on a rate-based model for absorber and stripper columns, ensuring accurate representation of mass and heat transfer. Thermodynamic behavior is captured using the Electrolyte Non-Random Two-Liquid (NRTL) model, with a detailed flowsheet that includes a packed-bed absorber, pressure-reduction valve, flash separator, and a stripper with integrated reboiler and condenser. Column internals, such as 2-inch Raschig rings, and full hydraulic analysis are included for equipment sizing and performance evaluation.

The simulation incorporates economic analysis and CO₂ emissions tracking, applying a carbon price of $51/tonne. Key results indicate a net negative CO₂ emission, capturing approximately 0.15 million tonnes of CO₂ per year, with a reboiler duty of 36 MW. The model provides valuable insights into energy consumption, solvent efficiency, and cost implications, offering a validated foundation for further process optimization, scale-up, and integration into carbon capture and natural gas treatment strategies.

Process Flow Diagram

Column Performance Analysis

The stripper column was modeled using a rigorous rate-based approach with 12 stages, including reboiler and condenser. Rich K₂CO₃ solvent enters at stage 2, where CO₂ and H₂S are effectively stripped, resulting in lean solvent regeneration. The reboiler duty is estimated at 36 MW, and the overhead acid gas stream contains high concentrations of CO₂ (80%) and H₂S (13.7%), confirming efficient separation.

Project Insights

Modeling and Design Accuracy

- Rate-based modeling ensures accurate mass and heat transfer predictions.

- Electrolyte NRTL model provides reliable acid gas absorption data.

Environmental Performance

- Captures approximately 0.15 million tonnes of CO₂ annually from natural gas.

- Achieves net negative emissions, supporting carbon reduction goals.

Energy and Utility Evaluation

- Reboiler duty of 36 MW indicates significant thermal energy requirement.

- Flash separation enhances overall energy efficiency of the system.

Economic and Operational Viability

- Economic evaluation includes carbon pricing to assess long-term viability.

- Results support scalability and cost-effectiveness of acid gas removal.

Conclusion

The Aspen Plus simulation successfully demonstrates the feasibility of capturing CO₂ from syngas using a potassium carbonate (K₂CO₃) absorption-stripping system. By applying the Electrolyte NRTL property method and rate-based column modeling, the process achieves accurate representation of thermodynamics and mass transfer behavior. Economic evaluation confirms that the system is cost-effective and environmentally favorable for industrial-scale deployment. Overall, the model provides a strong foundation for further process optimization, integration, and scale-up within carbon capture and utilization frameworks.