Process Modeling and Simulation of Olivine Mineral Carbonation for Sustainable Green Cement Production

Project Description

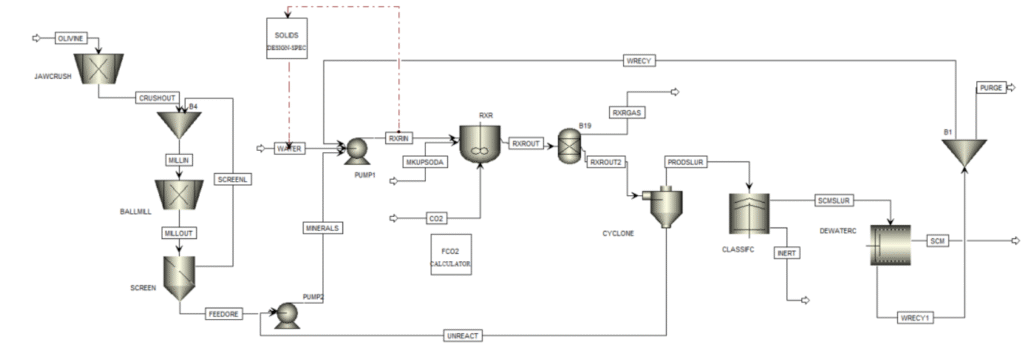

Mineral carbonation of olivine presents a viable pathway for reducing the carbon footprint of cement manufacturing by permanently sequestering CO₂ while producing supplementary cementitious material (SCM). Using Aspen Plus, a complete process flowsheet has been modeled, encompassing crushing, grinding, slurry-phase carbonation in a pressurized CSTR, hydrocyclone classification, and centrifuge dewatering.

The process design, based on a feed of 1000 kg/hr of olivine, achieves approximately 90% conversion of olivine to magnesium carbonate (MgCO₃) and silica (SiO₂). The resulting outputs include ~1040 kg/hr of SCM (40% silica, dry basis) and ~580 kg/hr of inert carbonates, with a net sequestration of about 620 kg of CO₂ per 1000 kg of olivine.

By enabling SCM blending of up to 20% into Portland cement and ensuring durable carbonate storage, the modeled system demonstrates both emission reduction potential and material sustainability. This work provides a structured foundation for future optimization, scale-up, and industrial integration of olivine carbonation in green cement production.

Project Objectives

The primary objective of this project is to evaluate and optimize the mineral carbonation of olivine as a sustainable solution for CO₂ capture, while exploring its application as a supplementary cementitious material (SCM). The study integrates process modeling to quantify performance, efficiency, and environmental benefits.

To design and simulate the olivine carbonation process for efficient CO₂ sequestration.

To determine conversion efficiencies and evaluate the reaction kinetics.

To assess the potential of carbonation products as SCM in cement production.

To establish a scalable framework for integrating mineral carbonation into industrial CO₂ mitigation strategies.

Process Modeling Methodology

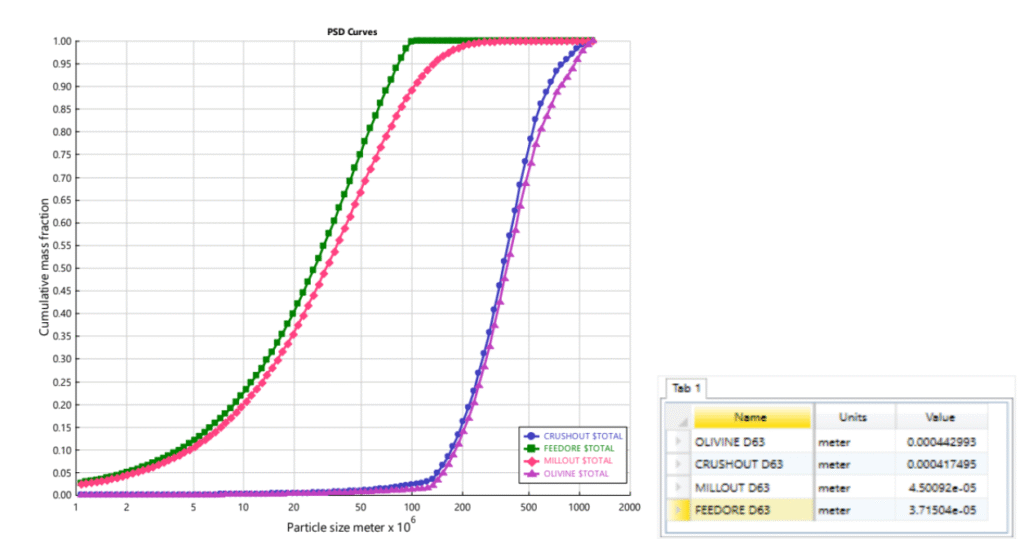

The Aspen Plus model represents key unit operations for olivine carbonation, including crushing, grinding, slurry preparation, carbonation reaction, solid–liquid separation, and dewatering. Particle size reduction is achieved through a crusher–mill system, with recycle of coarse fractions. A pressurized CSTR carries out the carbonation using CO₂ and NaHCO₃, achieving ~90% olivine conversion. Downstream classification separates silica-rich fines for the SCM product, while excess carbonate is discharged as an inert stream. The final dewatering step yields SCM at controlled moisture, with water and additives recycled to the reactor. The IDEAL property package is applied, with CO₂ treated as a Henry’s law component.

Modeling Outcomes

The Aspen Plus simulation of the olivine carbonation process was conducted at a design capacity of 1,000 kg/hr dry olivine feed. The model captures key aspects of particle size reduction, reaction conversion, separation efficiency, and CO₂ sequestration. Approximately 90% of olivine (Mg₂SiO₄) is converted into magnesium carbonate (MgCO₃) and silica (SiO₂) within the pressurized reactor. The product streams demonstrate high selectivity, with SCM containing ~40% silica and stable carbonate fractions suitable for permanent storage.

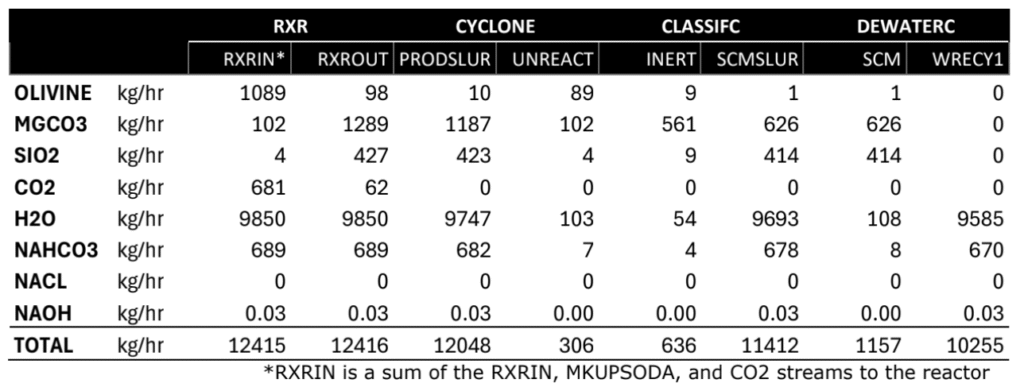

The main streams around the reactor and downstream separation units are summarized below. The hydrocyclone effectively separates coarse unreacted olivine for recycle, while the centrifuge enables the production of SCM at ~10% water content, ready for cement blending.

The simulation results confirm that the process yields approximately 1040 kg/hr SCM (dry basis) and 580 kg/hr inert carbonates (dry basis). The SCM can be blended into cement at up to 20% replacement by weight, providing a low-carbon construction material. In parallel, the inert carbonate stream offers a direct CO₂ sequestration pathway. Overall, the process captures about 620 kg CO₂ per 1000 kg olivine, with potential for even higher efficiency through CO₂ recycling and recovery enhancements.

Project Insights

Carbon Sequestration Potential

- Demonstrated ~620 kg CO₂ captured per 1000 kg olivine.

- Stable carbonate formation ensures long-term storage.

- Process aligns with global decarbonization targets.

Sustainable SCM Production

- Generated ~1040 kg/hr silica-rich material (~40% SiO₂).

- Product meets quality requirements for cement blending.

- Offers a low-carbon alternative to clinker production.

Process Efficiency & Separation

- Achieved ~90% olivine conversion under optimized conditions.

- Hydrocyclone and centrifuge enhanced particle classification.

- Recycling loops minimized resource losses.

Industrial & Environmental Integration

- Dual benefits of green cement production and CO₂ reduction.

- Scalable framework adaptable to cement plants.

- Contributes to circular economy through mineral valorization.

Conclusion

The modeling and simulation of olivine mineral carbonation demonstrate its strong potential as a dual-purpose solution—capturing CO₂ efficiently while producing reactive materials for green cement production. The study highlights favorable conversion efficiencies, viable reaction pathways, and clear opportunities for industrial integration. By coupling carbon sequestration with sustainable construction materials, the project offers a scalable pathway toward reducing emissions and advancing circular economy practices in the cement sector.