Catalytic Co-Hydroprocessing of Petroleum-Derived Heavy Gas Oil and Waste Cooking Oil for Hybrid Diesel Production

Description

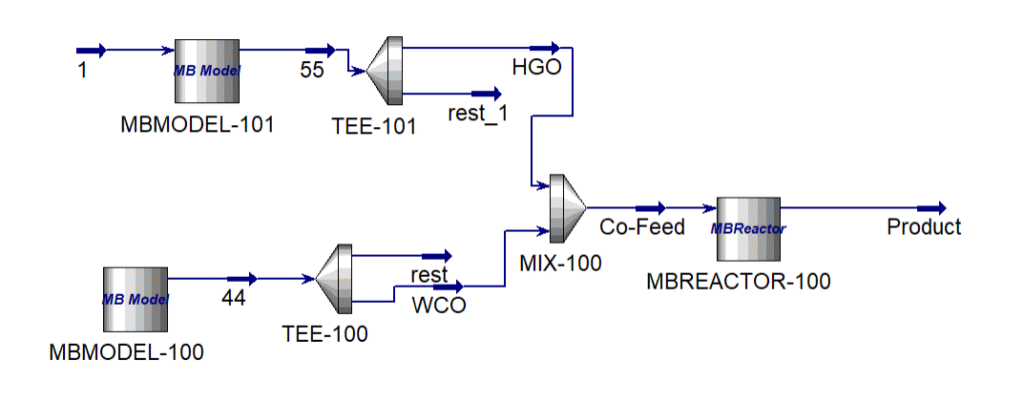

This project models the co-hydroprocessing of heavy gas oil (HGO) with waste cooking oil (WCO) for hybrid diesel production. The process leverages existing petroleum refining infrastructure to convert bio-based oils into cleaner fuels with minimal capital investment. HGO is characterized using molecular characterization, while WCO is represented using MB Model Container simulation. The mixture is processed through the MB Co-Feed Hydroprocessing Bed, where key reactions remove oxygen, sulfur, and nitrogen from the feedstocks. These transformations yield high-quality hybrid diesel that aligns well with experimental data in terms of nitrogen and sulfur content, conversion efficiency, and distillation behavior. The model demonstrates the feasibility of integrating renewable waste oils into conventional refining to produce sustainable fuels.

Process Flow Diagram

Project Insights

Strategic Significance

- Demonstrates the feasibility of integrating waste-derived oils into conventional petroleum refining without major infrastructure changes.

- Provides a transitional pathway toward renewable fuel adoption using existing refinery assets.

- Reduces the capital costs typically associated with constructing standalone biodiesel plants.

Technological Contributions

- Utilizes molecular characterization for heavy gas oil and advanced simulation models for waste cooking oil.

- Applies catalytic hydroprocessing reactions (HDS, HDN, HDO) for efficient removal of heteroatoms.

- Incorporates secondary reactions such as hydrocracking and aromatic saturation to improve fuel quality.

Performance Outcomes

- Simulation results align closely with experimental data for nitrogen, sulfur, conversion efficiency, and distillation profiles.

- Produces hybrid diesel with improved combustion quality and compliance with modern fuel standards.

- Demonstrates effective co-processing of renewable and fossil-based feedstocks for balanced energy production.

Industrial Relevance & Optimization Potential

- Offers a scalable approach for integrating renewable oils into existing refineries.

- Identifies opportunities for optimization and debottlenecking to enhance energy efficiency.

- Provides a practical model for producing sustainable hybrid diesel at reduced operational costs.

Conclusion

The co-hydroprocessing of heavy gas oil and waste cooking oil provides an efficient and sustainable approach for hybrid diesel production. The simulated process, validated against experimental data, demonstrates strong removal of sulfur, nitrogen, and oxygen impurities while maintaining high conversion rates. The integration of renewable feedstocks into petroleum refining infrastructure reduces the need for separate biodiesel facilities, making this approach both environmentally and economically advantageous. The study establishes a strong foundation for developing cleaner and more sustainable hybrid fuels using existing refinery technology.