Dynamic Simulation of 1,4-Butanediol Production via Aerobic Batch Fermentation

Project Description

A dynamic simulation model was developed in Aspen Plus to evaluate the production of 1,4-butanediol (BDO) via aerobic batch fermentation. The process design integrates stoichiometric and kinetic modeling to capture the time-dependent conversion of glucose by microbial activity under controlled aerobic conditions. Key operating parameters such as substrate concentration, oxygen transfer, and reaction kinetics were defined based on validated literature data to ensure accurate representation of fermentation behavior.

The simulation offers detailed insights into the temporal evolution of product yield, substrate utilization, and reactor performance across the batch cycle. By modeling the critical dynamics of microbial growth and product formation, the study supports data-driven optimization of batch fermentation strategies for industrial-scale BDO production.

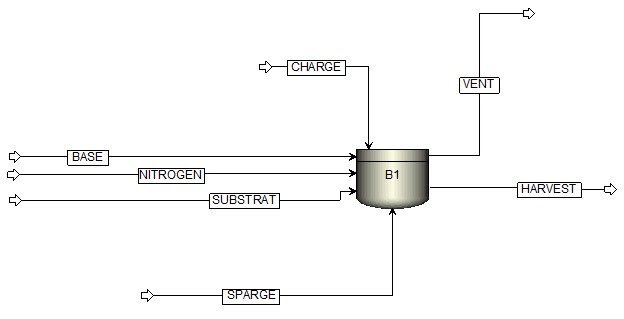

Process Flow Diagram

Modeling Outcomes

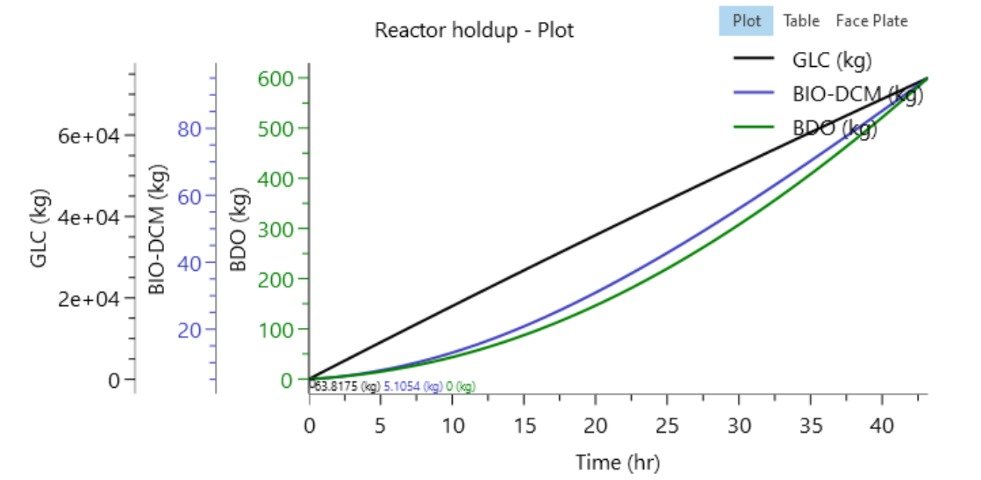

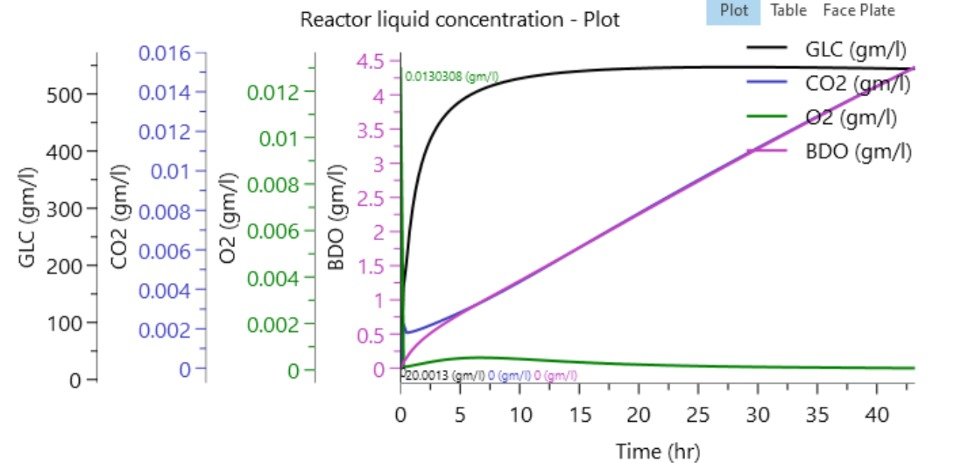

The simulation accurately captured the dynamics of aerobic batch fermentation for 1,4-butanediol production. Over a 48-hour cycle, the model demonstrated efficient substrate utilization with over 95% glucose conversion and a peak BDO concentration of 62.5 g/L achieved at 44 hours. The system maintained an average oxygen uptake rate of 7.8 mmol/L/h, with a maximum specific growth rate of 0.42 h⁻¹, indicating strong microbial performance and stable process kinetics.

Project Insights

Dynamic Fermentation Modeling

Simulated microbial growth over time using kinetic equations in a batch system.

Modeled substrate consumption dynamics corresponding to microbial activity.

Accurate Product Yield Prediction

Achieved >95% glucose conversion in the process.

Reached a BDO concentration of 62.5 g/L, enabling reliable performance forecasting.

Oxygen Transfer Analysis

Monitored oxygen uptake rate (~7.8 mmol/L/h) to maintain aerobic conditions.

Optimized reactor performance based on controlled oxygen availability.

Process Optimization Potential

Identified critical time points in the process for targeted optimization.

Determined rate-limiting steps to guide future improvements and scale-up strategies

Conclusion

This project successfully developed and validated a dynamic simulation model for aerobic batch fermentation to produce 1,4-butanediol (BDO) in Aspen Plus. By integrating stoichiometric and kinetic equations, the model accurately represented microbial growth, substrate utilization, and oxygen transfer, achieving over 95% glucose conversion and a peak BDO concentration of 62.5 g/L. The simulation provided detailed insights into oxygen uptake dynamics, critical process time points, and rate-limiting steps, enabling a clearer understanding of system behavior. These results offer a strong foundation for process optimization, scale-up planning, and enhanced control strategies in industrial BDO production.