Optimization of Cryogenic Integration for Hydrogen Liquefaction Systems

Description

This project models the integrated cryogenic process in large-scale hydrogen liquefaction plants (100 tonne/day). A novel process configuration is introduced, combining a mixed refrigerant (MR) cycle with Joule-Brayton refrigeration cycles for pre-cooling gaseous hydrogen from 25 °C to -182.8 °C. Subsequently, six cascade Linde-Hampson cryogenic cycles cool hydrogen further down to -253.0 °C. The process also incorporates ortho-para hydrogen conversion, essential for ensuring stability in liquid storage. This system provides a conceptual foundation for energy-efficient hydrogen liquefaction and can be applied in future plant and equipment design, optimization, and debottlenecking studies.

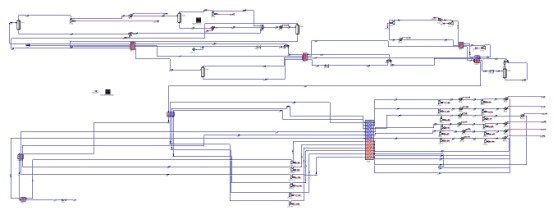

Process Flow Diagram

Project Insights

Strategic Importance

- Hydrogen liquefaction enables large-scale clean energy storage and transportation, supporting the global shift toward decarbonization.

- The process design aligns with international sustainability frameworks, such as the Paris Agreement.

- Provides a foundation for developing cost-effective and scalable infrastructure for the hydrogen economy.

Technological Advancements

- Introduces a multi-component mixed refrigerant (10 components) in pre-cooling, enhancing energy efficiency compared to conventional designs.

- Integrates Joule-Brayton cascade cycles for deep cryogenic cooling, ensuring high performance and operational reliability.

- Demonstrates seamless ortho-para hydrogen conversion, critical for liquid hydrogen stability during storage.

Performance Outcomes

- Achieves continuous large-scale hydrogen liquefaction at 100 tonne/day production capacity.

- Produces liquid hydrogen at -253.0 °C and 1 atm, with a para-hydrogen concentration of 99.86%.

- Ensures stable thermodynamic operation through staged pre-cooling and cryogenic cycles.

Industrial Relevance & Optimization Potential

- Highlights opportunities for process optimization, debottlenecking, and energy savings.

- Provides a scalable model for future industrial hydrogen liquefaction plants.

- Serves as a reference framework for designing next-generation systems in transport and power applications.

Conclusion

An innovative large-scale hydrogen liquefaction process was successfully modeled. The design utilizes advanced mixed refrigerant systems in the pre-cooling stage and cascade Joule-Brayton cycles in the cryogenic stage. The process reliably produces liquid hydrogen at -253.0 °C and 1 atm with 99.86% para-hydrogen concentration. This design can serve as a reference for next-generation hydrogen liquefaction plants, providing a pathway for cleaner energy storage and transport solutions.